ULTRACLEAN-3

ULTRACLEAN-3 est un concentré puissant pour le nettoyage des instruments chirurgicaux et dentaires dans un appareil de nettoyage à ultrasons.

Delivery forms

Documents

Where to buy

Explore ULTRACLEAN-3's Features and Benefits

Nettoyant puissant

Le nettoyant puissant supprime même les résidus les plus tenaces. Dans la plupart des cas, aucun pré ni post-nettoyage n'est nécessaire.

Application simple

Le bouchon de la bouteille contient des marquages de volume de 10 ml, 20 ml, 30 ml et 40 ml.

Adapté à l'usage dans les appareils de nettoyage ultrasonique

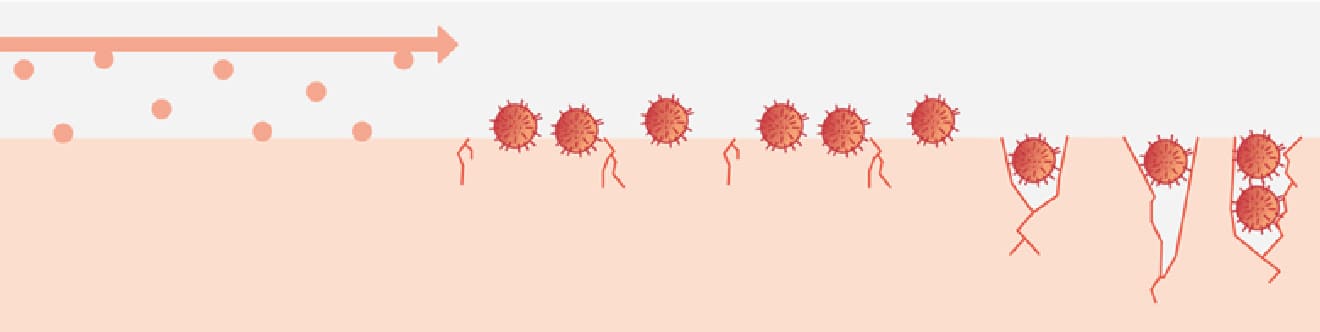

La puissance nettoyante du produit peut être augmentée en utilisant un appareil de nettoyage ultrasonique

Ensuring the Compatibility of Our Disinfectants Is a Top Priority

While no disinfectant can guarantee absolute compatibility with all materials, our rigorous in-house testing, strategic collaborations with medical device manufacturers, and stringent external testing at ISO 17025 accredited laboratories for final material compatibility evaluations-affirm that our disinfectants are exceptionally suited for a broad spectrum of surfaces, encompassing various metals, plastics, and polymers.

Note

Note

-

No visible surface damage or effect on the material is likely to occur when used according to label directions. No change to the integrity of the material is expected.

-

Some visible surface damage such as tarnishing or clouding may be seen with long-term exposure. Little to no effect on material intergrity is expected. Periodic wiping of surfaces with a clean damp cloth to remove residue can help to minimize damage.

-

Visible damage to the surface is likely to occur with long-term exposure and some effect on material intergrity is possible. Surfaces should be wiped with a clean damp cloth immediately after the contact time has been reached to reduce the risk of damage. Users should evaluate the risk of surface damage vs the benefits of disinfectant efficacy against pathogens to determine whether the products is appropriate for use.

The Diversity of Materials in Healthcare - From Metals and Plastics to Polymers - Makes Compatibility with Disinfectants Crucial

Recognizing and addressing material incompatibilities is crucial in the medical industry. Disinfectants that are not compatible with certain materials can trigger stress cracks in equipment, accelerating wear and tear and shortening their usable lifespan. Moreover, these cracks become breeding grounds for pathogens, rendering the disinfection processes ineffective. The longevity and functionality of medical devices hinge not just on the quality of their construction, but also on the interplay between the materials they are made of and the disinfectants used on them.

The Challenge of Environmental Stress Cracking

Environmental stress cracking presents a major issue in healthcare. When materials, notably plastics and polymers, come into contact with certain disinfectants, they can weaken and prematurely become brittle. The result is not just equipment that wears out faster but surfaces that become challenging to disinfect, turning into safe havens for pathogens.

This issue stems from the myriad of chemical structures that fall under the ❬ plastics ❭ and ❬ polymers ❭ categories. While device manufacturers choice of materials is influenced by their physical attributes, cost-effectiveness, and availability, the resilience to disinfectants is vital for patient safety.

On the other hand, disinfectants, which are made of active compounds, solvents, and other additives, need to strike a balance between eradicating microbes and not causing material damage. A lapse in this balance can lead to ❬ environmental stress cracking ❭, which weakens plastics prematurely. Prolonged exposure to certain disinfectants can alter polymer structures, making them brittle. Amines, for instance, are notably harsh on some plastics. The consequence? Deepening cracks in equipment, providing hiding spots for pathogens and undermining disinfection.

So what can be done? The remedy lies in a collaborative effort. While surface and device manufacturers should prioritize robust, durable materials, disinfectant producers must innovate with formulations that are gentler on surfaces, without compromising efficacy. At Oro Clean Chemie AG, our commitment echoes this principle, ensuring our disinfectants are both potent and compatible, so you never have to choose between clinical efficacy and equipment longevity.

Getting the Most Out of ULTRACLEAN-3

Utilisateurs visés

Le produit est prévu pour une utilisation par des professionnels dentaires ou de la santé possédant des connaissances concernant la désinfection des dispositifs médicaux. Le produit ne doit pas être utilisé directement sur les patients.

Notice d'utilisation

Pour votre protection, portez une blouse de laboratoire, des gants de ménage et des lunettes de sécurité. Préparer la solution active conformément au tableau de dosage. Utiliser un appareil de nettoyage par ultrasons pendant 30 minutes. Après le nettoyage, rincer abondamment les instruments à l'eau courante d'au moins une qualité d'eau potable pendant 10 secondes. Remplacer la solution active tous les jours ou lorsqu'elle est visiblement contaminée. Respecter les recommandations de retraitement du fabricant de l'instrument. Ne convient pas pour le nettoyage d'instruments à code couleur et d'instruments entièrement ou partiellement constitués de poils naturels, de nylon ou d'aluminium. Une liste des matériaux compatibles et incompatibles est disponible sur notre site web. Si vous n'êtes pas sûr de la composition du matériau du dispositif médical, contactez le fabricant avant utilisation. Tout incident grave survenu en lien avec le dispositif devrait faire l'objet d'une notification au fabricant et à l'autorité compétente de l'État membre dans lequel l'utilisateur et/ou le patient est établi.

Limites

POUR USAGE PROFESSIONNEL SEULEMENT. Ne pas mélanger avec d'autres produits.

Dosing Table

|

Concentrate

|

+ |

Water

|

Time

|

|

| 5% | 50 ml | + | 950 ml | 30 min |

Use Steps

1

For your protection, wear a laboratory gown, household gloves and safety goggles.

2

Prepare the working solution according to the dosing table.

3

Use an ultrasonic cleaning device for 30 minutes.

4

After cleaning, rinse instruments thoroughly under running water of at least drinking quality for 10 seconds.

Manipulation

Danger Peut être corrosif pour les métaux. Provoque des brûlures de la peau et des lésions oculaires graves. Ne pas respirer les fumées/brouillards/vapeurs/ aérosols. Porter des gants de protection/des vêtements de protection/un équipement de protection des yeux/ du visage. EN CAS D’INGESTION: rincer la bouche. NE PAS faire vomir. EN CAS DE CONTACT AVEC LA PEAU (ou les cheveux): Enlever immédiatement tous les vêtements contaminés. Rincer la peau à l’eau/Se doucher. EN CAS DE CONTACT AVEC LES YEUX: rincer avec précaution à l’eau pendant plusieurs minutes. Enlever les lentilles de contact si la victime en porte et si elles peuvent être facilement enlevées. Continuer à rincer. Eliminer le contenu/récipient conformément aux réglementations locales/nationales. Pour plus d'informations, veuillez consulter la fiche de données de sécurité disponible sur notre site web.

Accessoires d'application

User Friendly Packaging

Packaging Details

Primary Packaging

Primary PackagingColor-Coded Closure

The color-coded closure quickly indicates the product's application area, reducing the risk of misuse and enabling faster identification of the correct product.

Measuring Closure

The measuring closure allows the user to precisely dose the disinfectant concentrate, ensuring effective disinfection.

Clearly Visible Effective Spectrum/Exposure Time

The contact time clearly stated on the label informs the user exactly how long the disinfectant must be left to take effect.

Ergonomic Bottle Design

The ergonomic bottle is designed for easy handling and application, enabling a more efficient and simple use of the product.

Label with Image of Application Area

The label includes an image for the product's application area, minimizing the potential of using the wrong product, especially in hectic working environments.

Tamper-Evident Closure

The tamper-evident closure guarantees the integrity of the product and provides the assurance that it has not been opened or contaminated.

Booklet Label with 30+ Languages

The multipage label include translations in over 30 languages, facilitating ease of use for a multicultural workforce.

Dosing Table

The label of our disinfectant concentrates includes a dosing table that clearly indicates the quantities of concentrate and water needed to prepare the working solution.

Bottles Made of Recyclable HD-PE Material

Promotes environmental sustainability by ensuring the packaging can be fully recycled, safeguarding resources for future generations.

Secondary Packaging

Secondary Packaging Pallet

PalletDiscover More About ULTRACLEAN-3

Composition pour 100 g

100 g contiennent 16 g d'hydroxyde de potassium, des inhibiteurs de corrosion, des auxiliaires et de l'eau.